© Øverli Propartner

REACTOR TRACER TESTING

How to detect non-ideal behavior of an

anaerobic digester

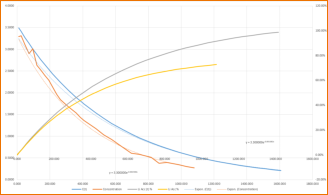

Tracer testing involves the addition of an inert tracer to a process unit and measurement of tracer concentration in the process effluent. Subsequent analysis of the tracer data allows identification of such non-ideal behavior as short circuiting, dead zones, and deviations from assumed hydraulic characteristics such as complete mix and mapping of active vessel volume. Tracer testing can be applied to any full-scale treatment unit to identify deviations in hydraulic characteristics. Experience indicates that the hydraulic performance of many full-scale treatment units is highly non-ideal, and that numerous opportunities exist to optimize their performance. A tracer test can be carried out without disturbing a continuous process. The alternative is often an operational shutdown, perhaps for up to a week, to open the tank for sediment content mapping. It will by only physical inspection of the tank not be possible to reveal any short circuits and the quality of the mixing. The graph on the right shows an analysis of the theoretical and actual active volume in a digester. From this, the inactive volume is found.